Description

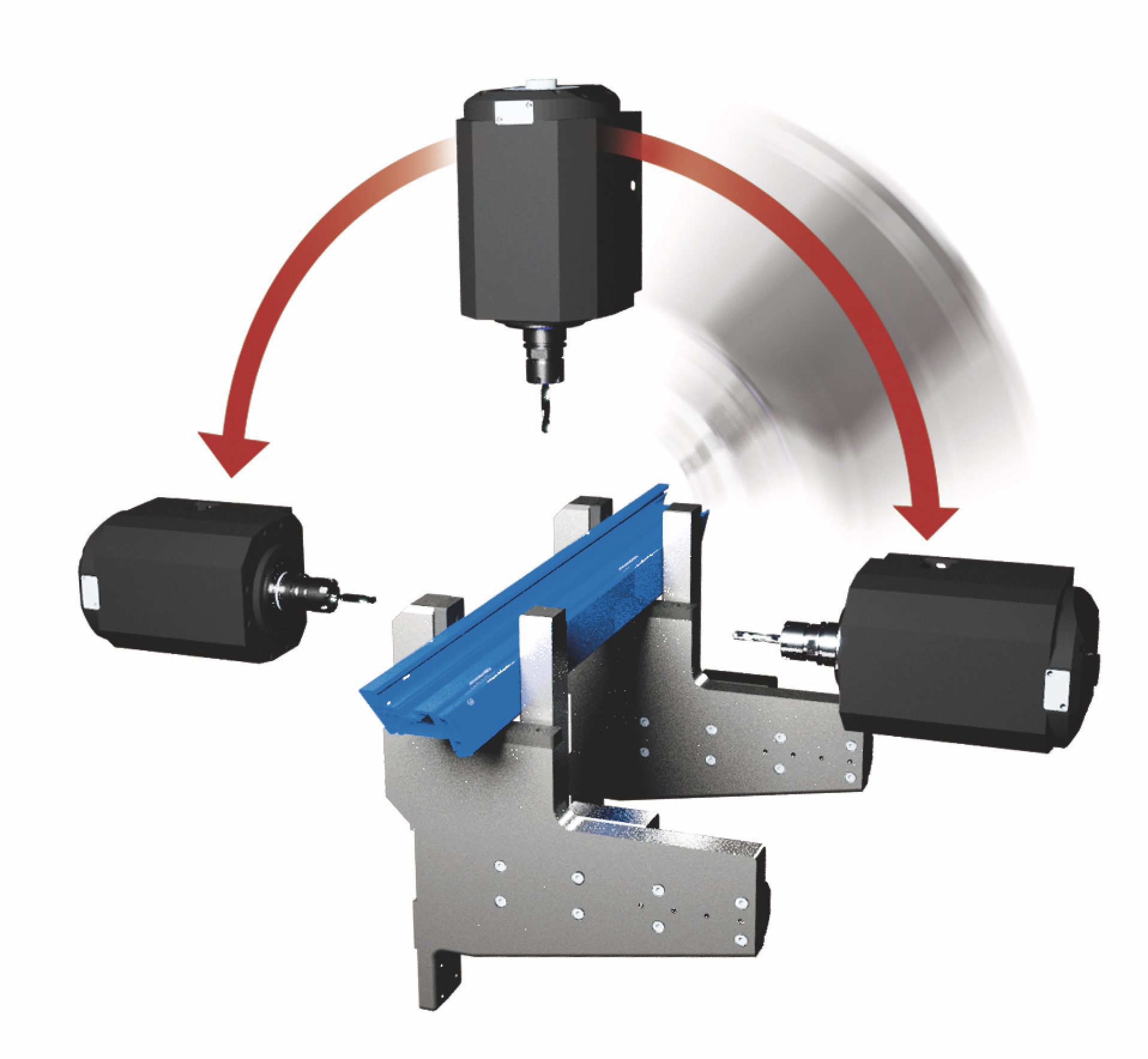

The P107 can access three faces (top, back, front) and the two ends of a profile and perform various operations on any of these faces in a single program. Using a total of four axis the machine can manipulate the spindle to all almost unlimited possibilities without operator interference. Programming is simple yet powerful thanks to the in house developed Pertici PCAM software that manages all aspects of the machines operation. Tool changes are completely automatic as is the position of all material clamps.

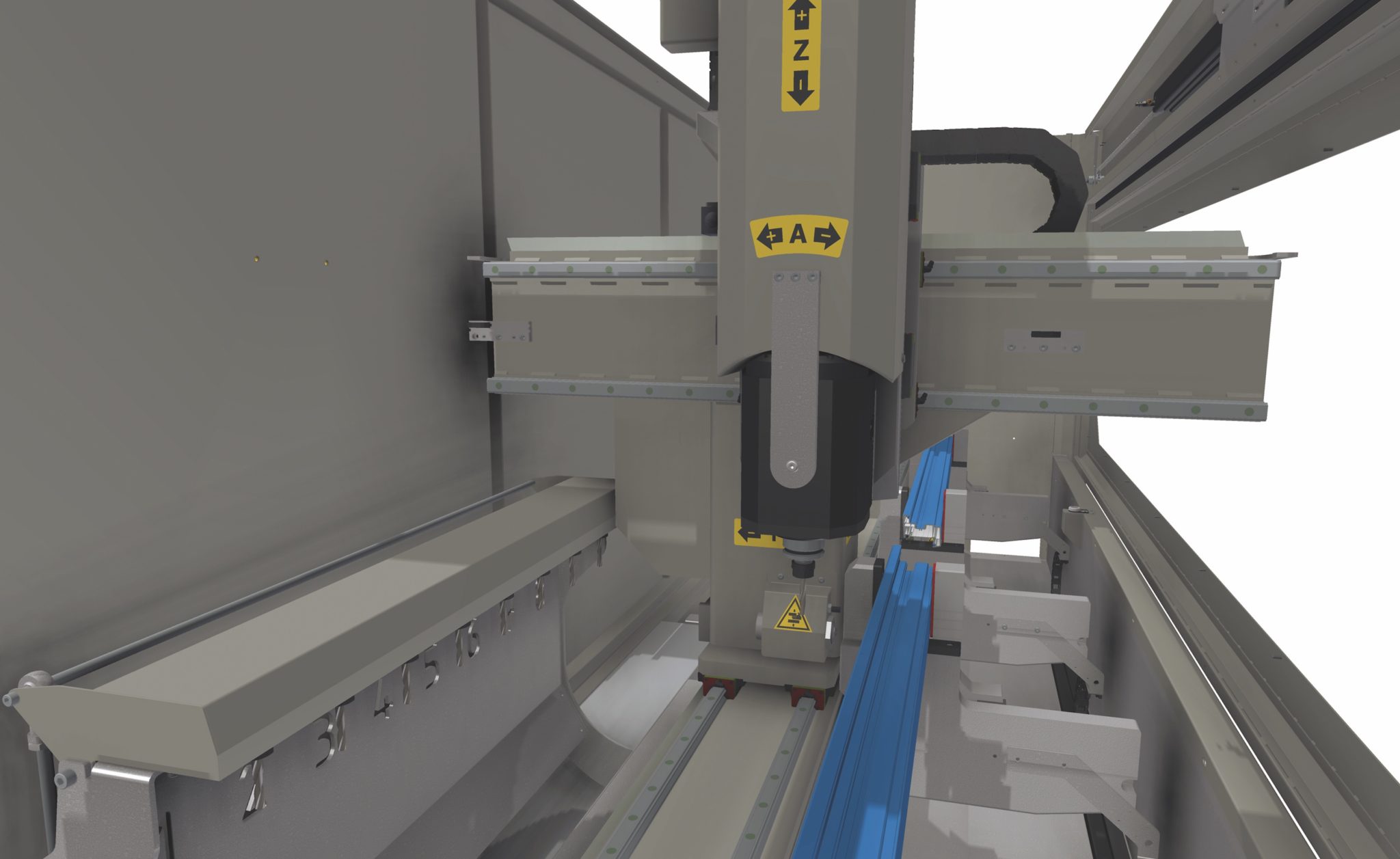

The machining head moves in longitudinal, transversal directions by brushless motors with rack and pinion system allowing the movement on ball bearings rails and slides to achieve very high precision. The vertical axis is driven by a super precise recirculating ball screw and brushless motor. The rotation of the spindle motor between -90° to +90°allows machining operation on all faces of the profile at any angles.

The P107 is ideal for either complex “one off” jobs, several variations on the same job or mass production of the same job. It doesn’t matter. The machine can quickly change from one job to another or is happy to plod along doing the same job 1000 times over.

Three models are available according to various length and versions to meet customer.

Features:

- 4 CNC controlled axis

- X axis maximum travel (longitudinal): 7225mm

- Y axis maximum travel (transversal): 790 mm

- Z axis maximum travel (vertical): 400 mm

- A axis maximum travel -90° ÷ +90°

- X Axis Rapid Max Speed: 90 m/min

- Y Axis Rapid Max Speed: 50 m/min

- Z Axis Rapid Max Speed: 15 m/min

- A Axis Rapid Max Speed: 7,200º/min

- Electrospindle power: 5 kW

- Electrospindle maximum speed: 18000 rpm

- Tool Magazine: 8 tools

- Tool change is fully automatic

- Maximum diameter of milling tool: 20mm

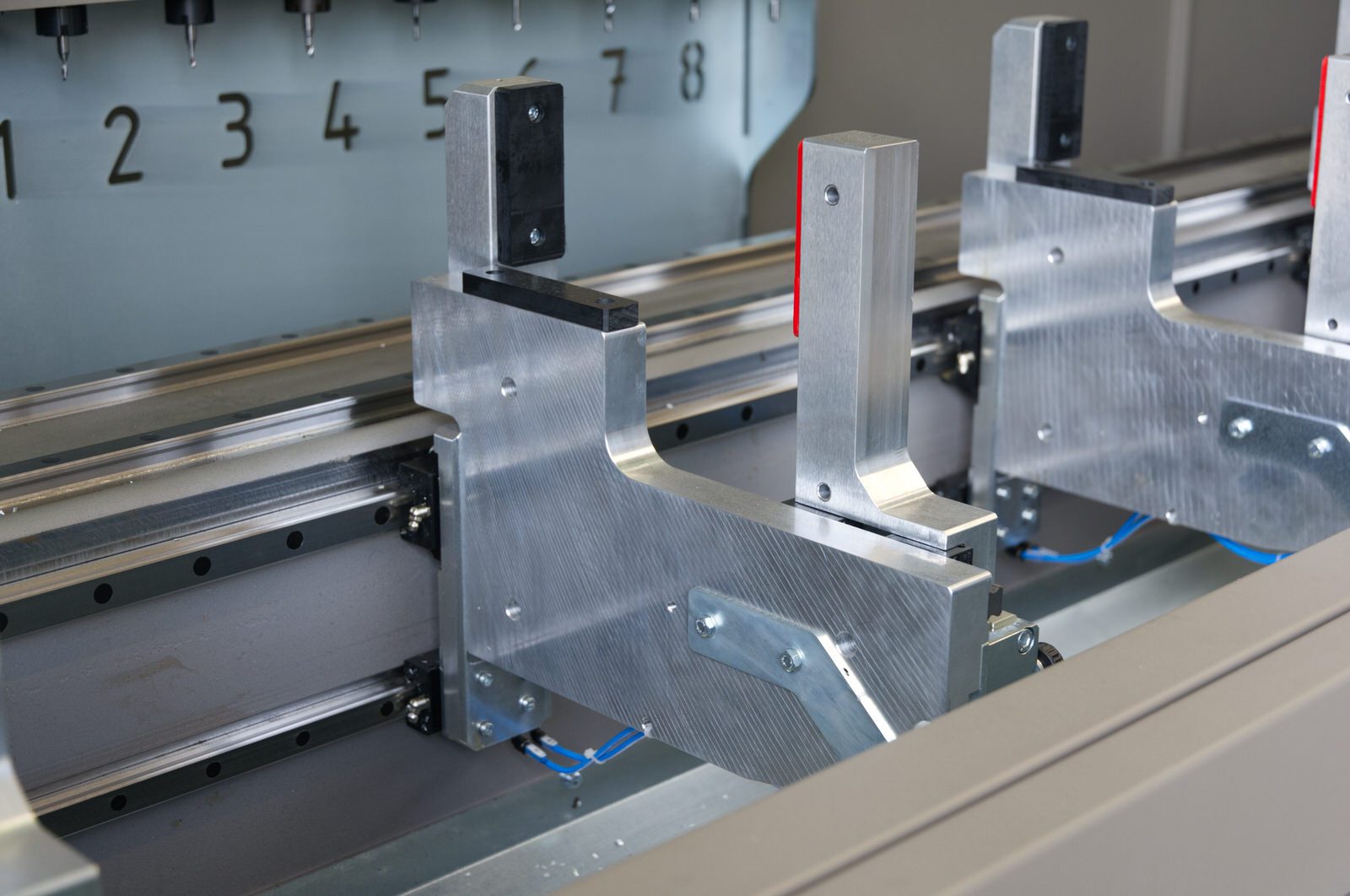

- Number of standard clamps: 8

- Clamp positioning is fully automatic using main carriage to position each clamp

- Number of profile end stops: 2

- Micro lubrication system fitted as standard

- Automatic front protection door: 2

- Power supply: 8,5 kW

- Air consumption: 165 L/min

- Dimensions P107 (length x depth x height): 8100 x 1750 x 2140 mm